Consensus community valuation

Straws are discrete research notes that relate to a particular aspect of the company. Grouped under #hashtags, they are ranked by votes.

A good Straw offers a clear and concise perspective on the company and its prospects.

Please visit the forums tab for general discussion.

Latest from Hazer - a MOU with a Swedish-listed global chemical company specializing in water treatments.

It's not specifically stated, but my assumption is that it's the graphite that Kemira is interested in.

Only an MOU to investigate potential use, but interesting in that it's seemingly on the graphite side and not the hydrogen side of Hazer's technology equation.

Purely FYI, from the HAZER shareholder letter received Dec 19, 2025:

>>>>>>>

2026 is shaping up to be pivotal year for our commercialisation. Our focus is clear: convert our global pipeline into licence opportunities, advance projects to investment-ready status and begin creating commercial value from both hydrogen and graphite. We are targeting both established and new markets - liquid fuels, green steel, power generation and advanced materials - where low-cost, low-emission hydrogen and graphite are increasingly in demand.

Government engagement continued to strengthen through 2025, including direct engagement at both Federal and State level, resulting in closer alignment with major decarbonisation funding programs. This support positions us well for accelerated deployment in Australia. Policy settings are evolving to better recognise alternative low-emissions hydrogen pathways, including methane pyrolysis as a viable low-cost solution.

Last Friday we announced an agreement with M Resources, with the Hazer Process incorporated into their proposal for the Whyalla Steelworks. This engagement is further validation and highlights the relevance of our clean hydrogen and graphite in low-emissions steelmaking and reinforces the growing interest in methane-pyrolysis solutions within major industrial sectors.

During the year, we also delivered our first commercial activity under the KBR alliance, signing an agreement with EnergyPathways in the UK for a 20,000 tonne per annum clean hydrogen facility to be integrated into their ammonia project. With national significance status, this project is a major platform for broader UK and European opportunities and is now revenue generating with the commencement of the engineering studies scope.

Our graphite strategy advanced meaningfully. Global supply pressures—tariffs, export controls and critical mineral classification—have increased demand for alternative supply sources. Testing, partner engagement and our collaboration with Mitsui all progressed strongly this year, supporting graphite monetisation as a second revenue stream for the Hazer Process.

Underpinning all of this was the performance of our Commercial Demonstration Plant, which confirmed high reliability, stable hydrogen production and high-quality graphite at scale. This remains the technical foundation of our global scale-up strategy.

We end the year with a strong foundation and robust funding position, world-class partners, a global pipeline of advanced opportunities and a technology ready for deployment. We believe 2026 will be the most significant value-creation year in Hazer's history.

<<<<<<<<<

Nothing new, but it’s nice to see it all laid out succinctly. Now to see if they deliver on the promise. Onwards 2026!

12/12/2025: Nice bump in the HZR SP today on the back of this announcement:

HAZER TECHNOLOGY SELECTED FOR WHYALLA CLEAN STEEL BID.PDF

That was a screenshot from a few minutes ago - the share price will obvious move around today but a +22% gain early in the trading day is a nice start.

Here's the announcement:

Disclosure: I hold HZR (0.9% based on yesterday's closing share price of $0.41, will be higher now). I hold it in my speccy PF.

Discl: Held IRL 2.10% and in SM

A bit of Shares On Issue and Share Options movement, over 3 separate ASX announcements, in Hazer Group yesterday, which needed a bit of unpacking.

In summary:

- These are follow up actions from the resolutions passed at the AGM

- They ensure Glenn Corie is sufficiently incentivised to continue the good things he is doing for the next 3 years

- Both Glenn and the Board are backing the company with very decent chunks of their own coin, immediately, and over the next 3 years - this injects cash into HZR, increases their personal skin in the game and demonstrates their confidence in where HZR is going in a very tangible way

Issue of Glenn Corrie Short Term Incentive Bonus

Glenn Corrie, the MD&CEO received 120,853 free shares as part of his short term incentive bonus - at $0.41, that nets him $49,550, a fair amount I think given the progress he has steered since he joined.

Issue of Tranche 2 Placement Shares to CEO and Directors

3,445,160 shares were issued at $0.31 to Directors and Management.

4 of the 5 directors took up the placement, presumbly with their own coin, including Glenn Corrie, stumping up between $50k and $453k, each - see table. This is some serious coin and demonstrates good confidence in the company’s future prospects. Raises about $1m of capital - very handy indeed.

Issue of 5 Year Director Share Options

Different Directors and the MD/CEO have different vesting conditions.

Glenn Corrie’s vesting lines up with his new 3-year extension tenure.

Hazer really seems to be at a fascinating stage of development. Taking Glenn at face value, the hard R&D and validation work is done, they’ve secured a major licensing partner, and they have a huge addressable market with a decent pipeline

According to Glenn, the NPV of just a few contracts suggests the company is heavily undervalued. He reckons $80-100m per contract over 20 years (at a 10% discount rate), with each expected to generate about $10m per plant per year. Since it’s a licensing model, it should be highly scalable with fat margins. At least in theory.

Crucially, the tech seems supported by hard economics, not just environmental feel goods. The strategic/geopolitical angle is also interesting given most graphite currently comes from China.

The market is clearly skeptical.. and no wonder given how poorly 'climate-tech' has performed recently. But that, I suppose, is the (potential) opportunity. As Glenn said, a decent commercial contract or two could trigger a serious re-rate, so the next 12 months will be interesting.

Of course, the risks are real: contracts might not materialize, they could burn through funding too fast, or simply get outcompeted (or ignored) by customers. Like any new tech, there are always unforeseen gremlins (which Hazer has seen before). Plus, there’s counterparty risk with KBR, and the lag between signing a deal and actually seeing the cash will likely be material.

But it’s certainly interesting. If the tech is as good as advertised, and if they land some big contracts, this really could be a multi-billion dollar company down the track.

Anyway, it's on a watch-list for me at this stage.

Here's the transcript: Hazer Transcript.pdf

And some AI generated notes from the meeting:

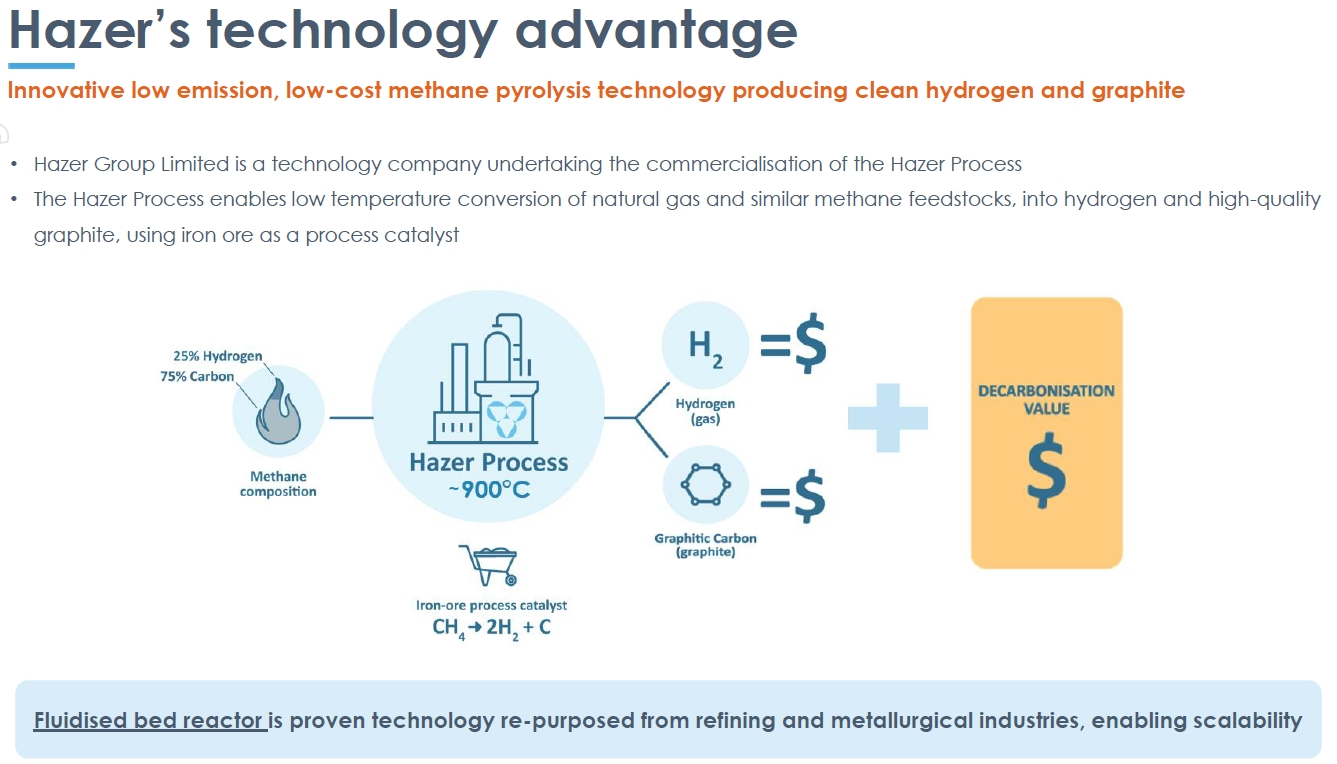

The Core Tech & Process

- Methane Pyrolysis: Hazer uses a proprietary technology to split natural gas (methane) into two products: clean hydrogen and solid graphite.

- The Secret Sauce: The process uses an iron ore catalyst in a "fluidized bed reactor." This is 100-year-old proven industrial equipment, meaning it scales easily compared to newer, unproven methods.

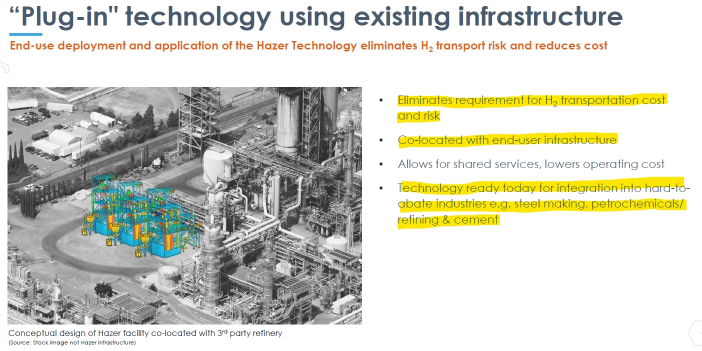

- Plug and Play: The tech is designed to "plug in" to existing industrial plants (refineries, steel mills) to replace their current dirty hydrogen production units without disrupting the rest of the facility.

The Economics (The "Moat")

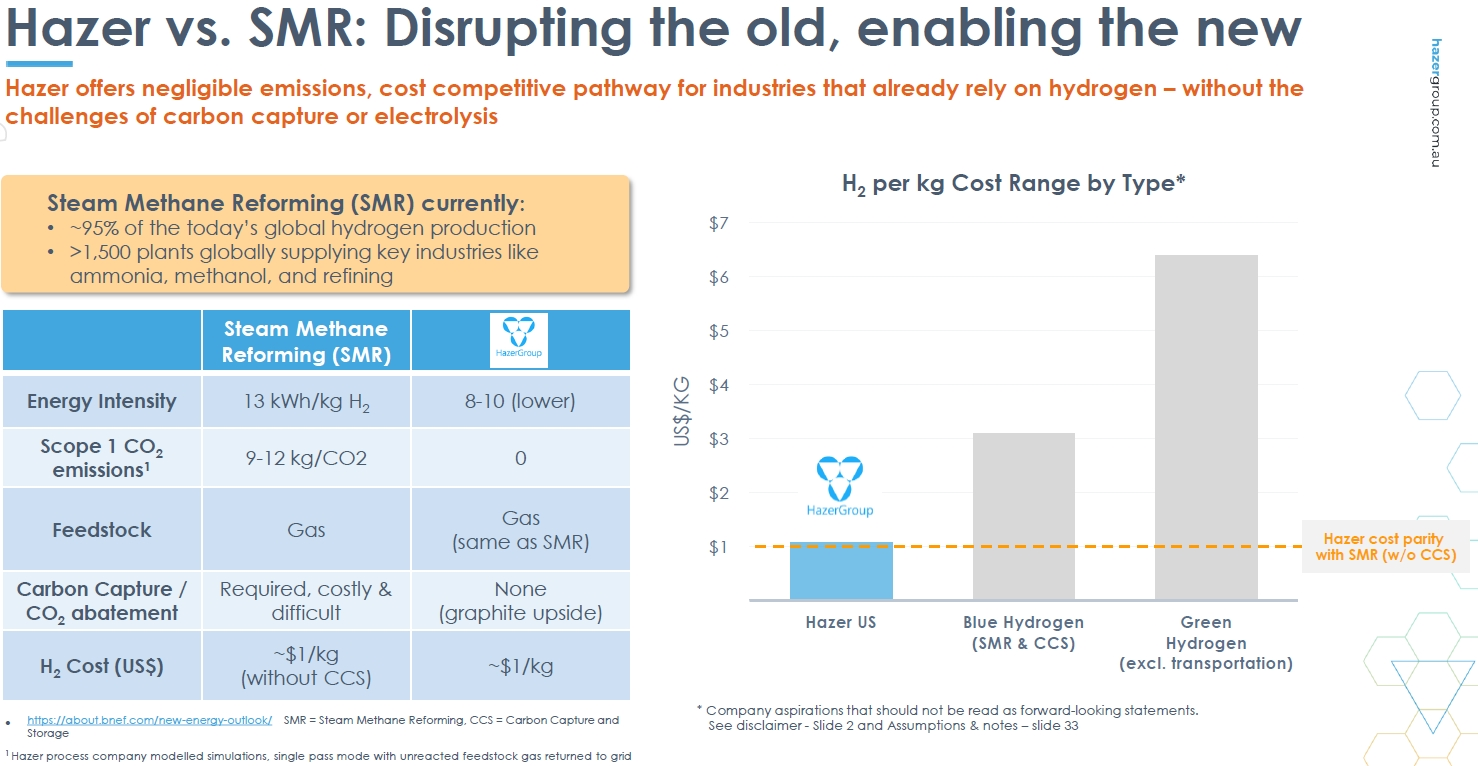

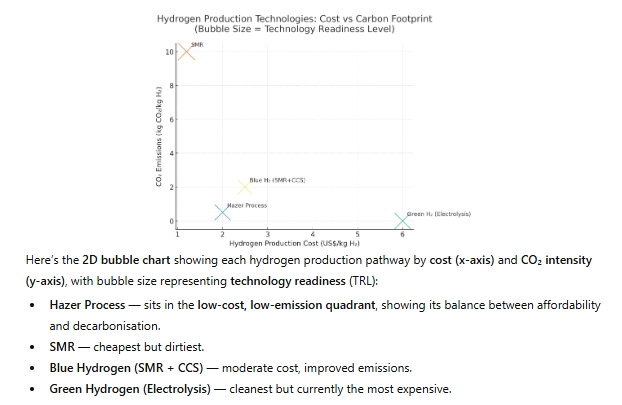

- Cost Parity: Hazer claims they can produce clean hydrogen at the same cost as traditional dirty methods (Steam Methane Reforming).

- US Cost: ~$1/kg (vs. ~$8/kg for green electrolysis).

- Australia Cost: ~$1.50–1.60/kg (vs. >$15/kg for green electrolysis).

- Energy Advantage: The process is extremely energy-efficient, requiring only 7–8 kWh to produce a kilo of hydrogen (green hydrogen via electrolysis needs ~55 kWh).

- Subsidy Independent: Because they have cost parity, the model works economically without needing government handouts or carbon credits, though those would be pure upside.

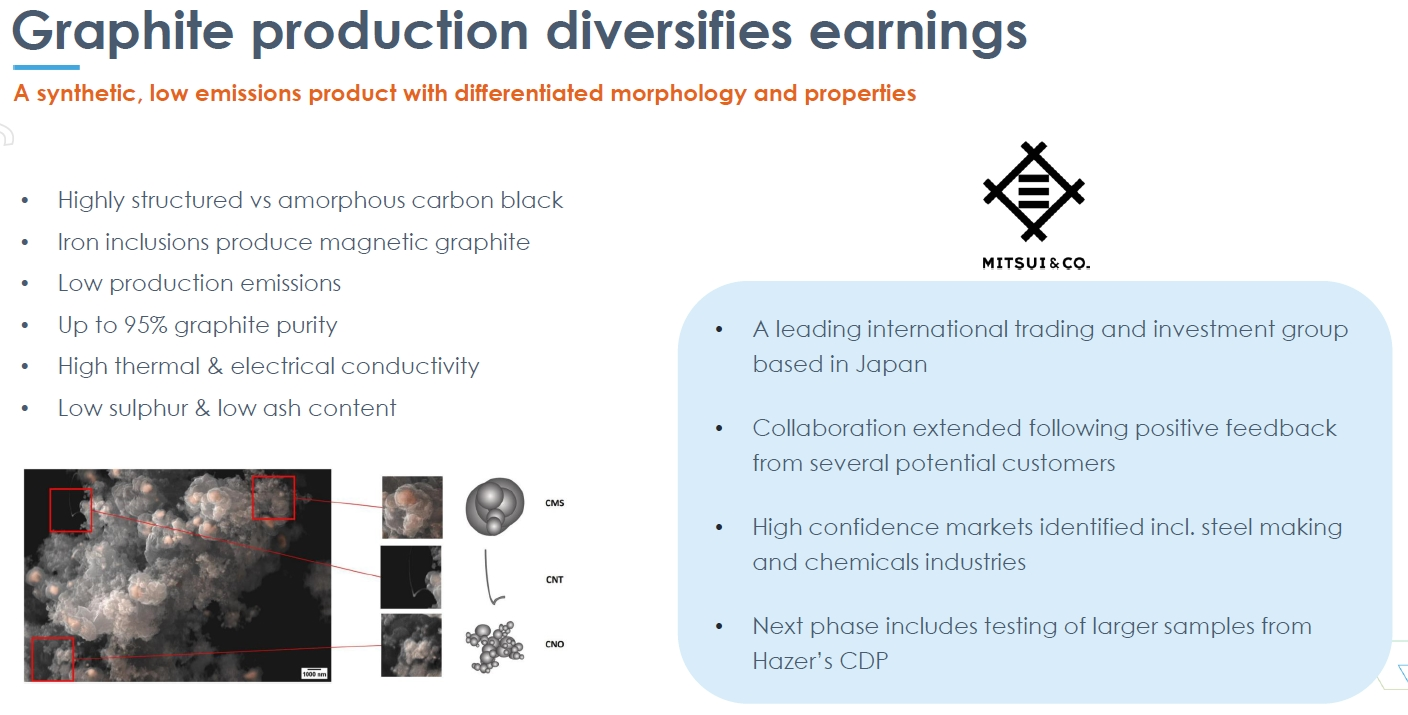

The Graphite Bonus

- Dual Revenue: For every ton of hydrogen produced, the process creates roughly 3.5 tons of graphite.

- Geopolitical Hedge: Over 85% of the world's graphite currently comes from China. Hazer offers a way for Western nations to produce their own graphite (critical for EVs and batteries), mitigating sovereign supply risk.

Business Model & Strategy

- Licensing Model: Hazer is "CAPEX light." They don't intend to build and own huge plants; they license the tech to operators.

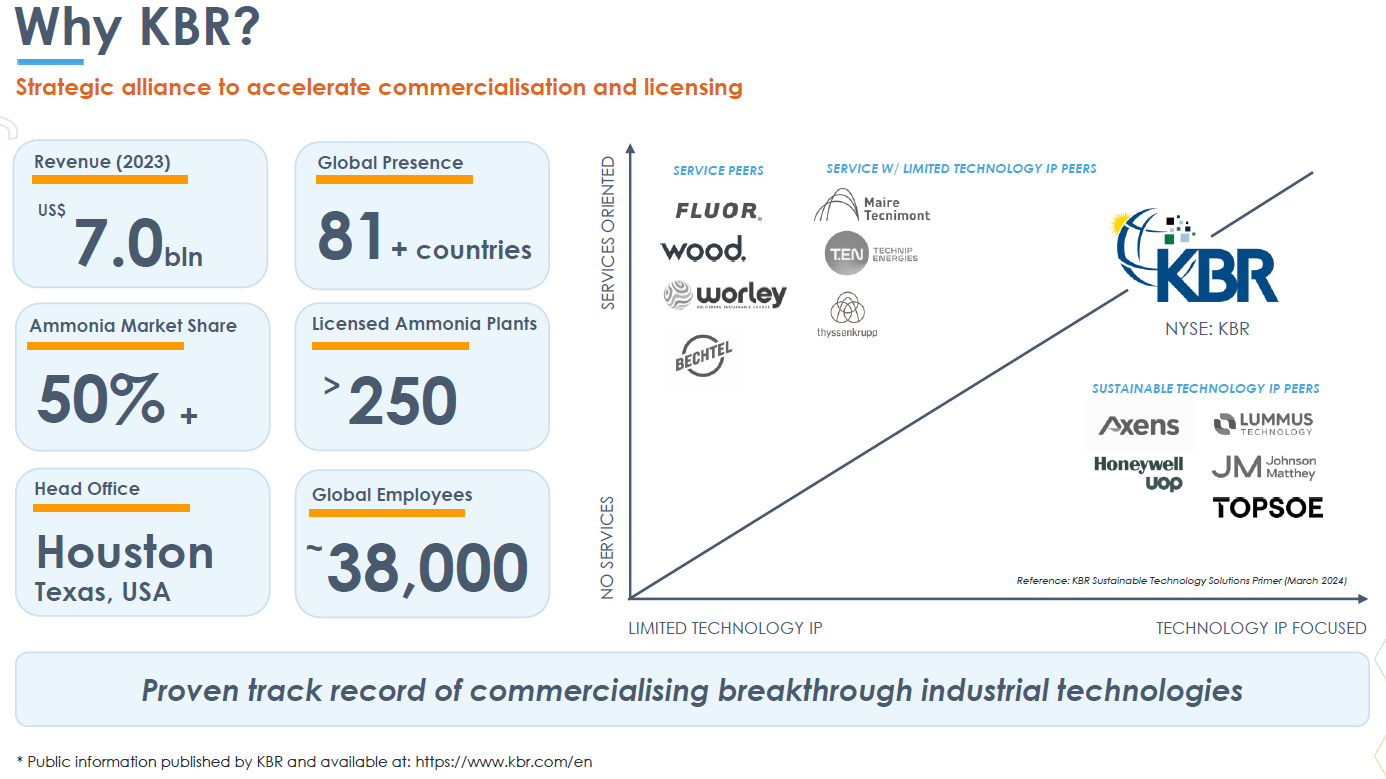

- KBR Partnership: They have a strategic alliance with engineering giant KBR. KBR acts as their global sales force and engineering partner (exclusive for the ammonia and methanol sectors), allowing Hazer to scale without adding massive headcount.

- Revenue Potential: Management targets ~$10 million per year in license fees per plant.

- Valuation: Glenn estimates the NPV (Net Present Value) of a single commercial project at $80–100 million. With a market cap of ~$130 million and a pipeline of ~50 projects, he views the company as significantly undervalued.

Commercial Status

- Readiness: The tech is at TRL 7/8 (Technology Readiness Level), meaning the R&D is effectively done and it is in the "Commercial Demonstration" phase.

- Validation: ExxonMobil recently entered the methane pyrolysis space, which Glenn sees as a massive validation that this specific technology route (rather than just green hydrogen) is the future.

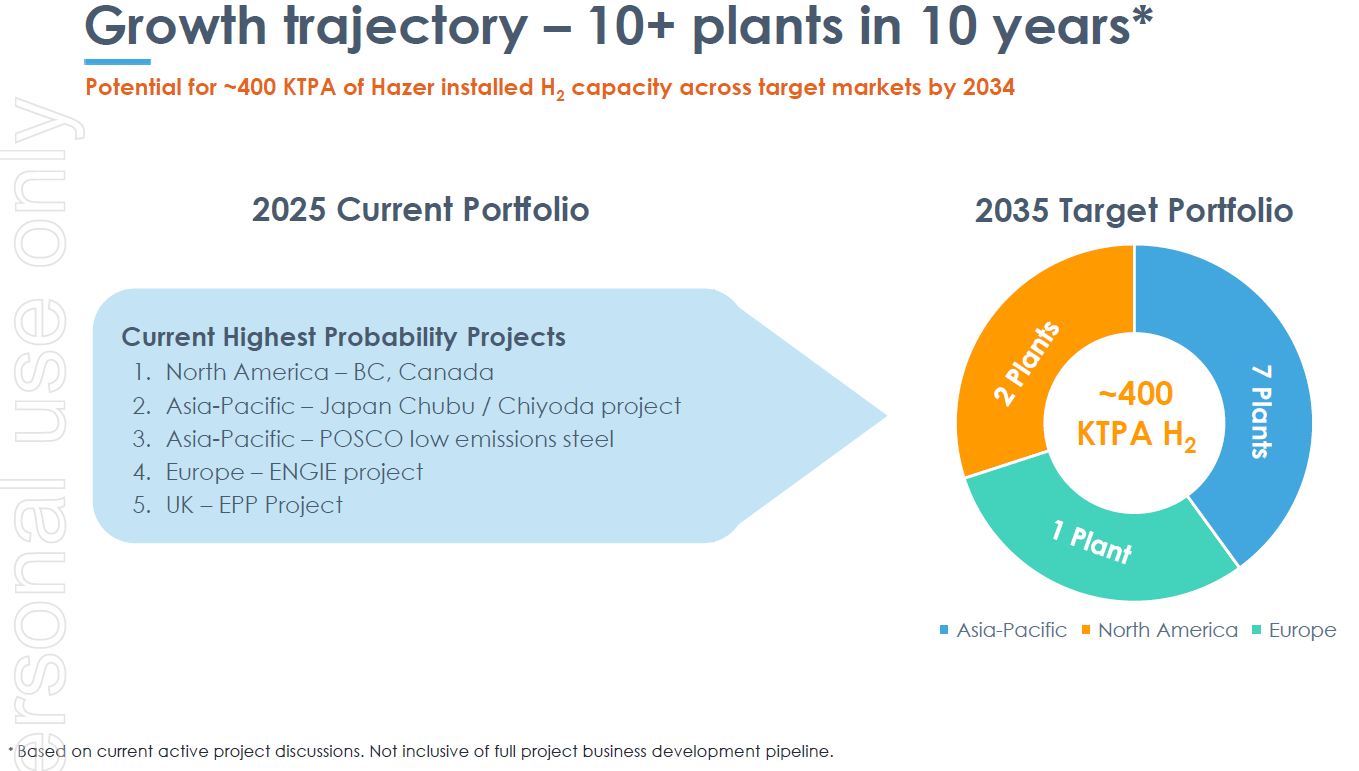

- Key Projects: They are progressing projects in Canada, Japan (Chubu Electric), and the UK (Energy Pathways). The UK project recently moved to a paid feasibility study.

Risks & Competitors

- Competitors: The main competitor is Monolith (US), a private company valued at ~$1–2 billion. Monolith uses plasma tech (higher energy) and produces carbon black (tires) rather than graphite (batteries).

- Cash: The company has ~$20 million in liquidity, which is expected to bridge them through upcoming licensing milestones over the next year.

- Next 12 Months: The focus is purely on converting the pipeline into binding commercial licenses ("The Year of Commercialization").

Discl: Held IRL 1.29% and in SM

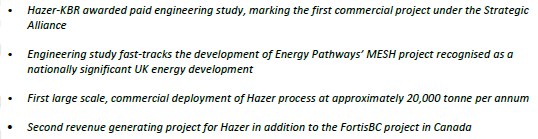

A very nice thesis reaffirming announcement from HZR for me this morning.

3 positive things:

1. The contractual position for EEP moves from MOU to Binding Agreement for a paid engineering study, adding to commercial revenue generation.

2. The commitment comes really quickly, in relative terms, from the MOU signed with EEP on 15 July 2025. EEP moving at pace on the back of FortisBC is really positive for momentum.

3. It is the first commercial project from the KBR-HZR alliance - I thought the alliance was a huge step in increasing the potential of HZR's journey in the ammonia market. This win helps reaffirm that thinking.

Discl: Held IRL 0.72% and in SM

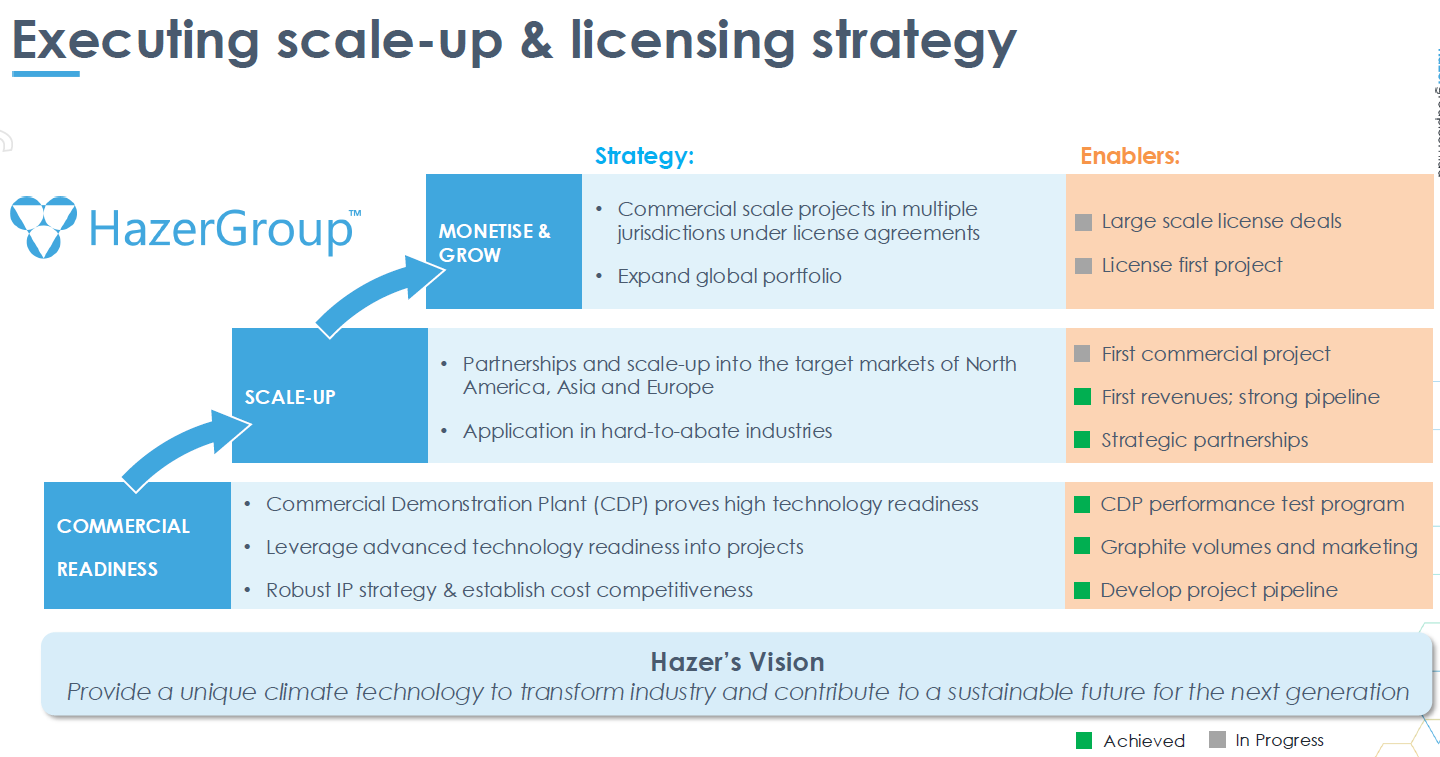

This is how the various pieces of the HZR story comes together for me - the Scale Up, Commercialisation and Licensing Strategy.

SUMMARY

1. Technology is proven and de-risked via the Commercial Demonstration Plant - the hard yards and cost investment to prove the technology is now behind HZR

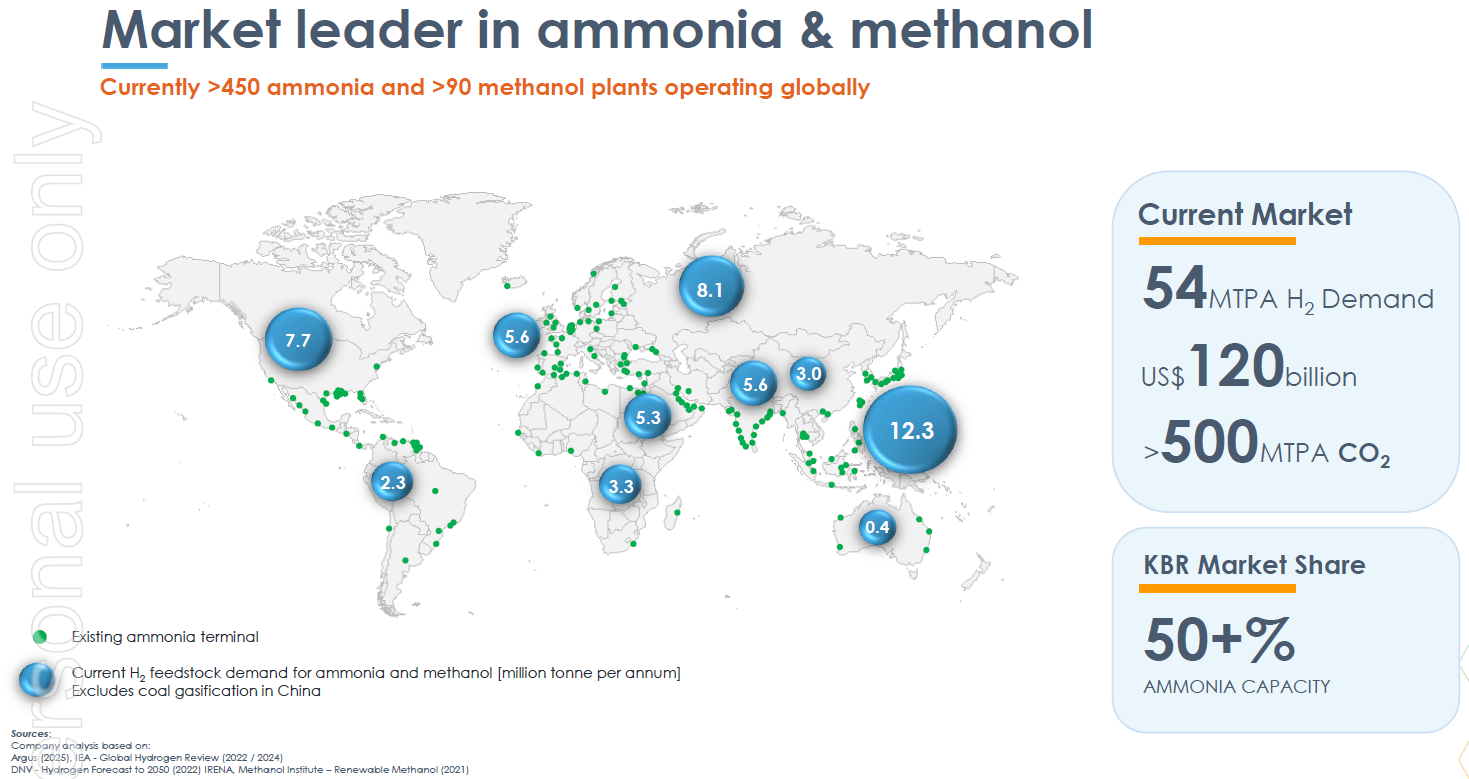

2. The KBR Alliance locks in KBR, with its ~50% market share of ammonia and methanol plants, exclusively on the Hazer technology, the key ammonia and methanol markets, its plant engineering expertise and its sales and marketing expertise/salesforce in these markets

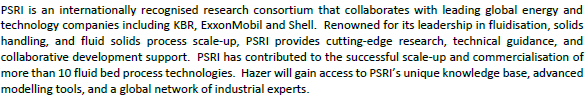

3. The PSRI partnership enables HZR to leverage PSRI’s expertise in fluidisation fundamentals as it realtes to Hazer’s use of fluid bed reactors as a core part of the Hazer process and its primary competitive advantage

4. Ongoing marketing partnership with Mitsui to unlock potential, find and lock in offtakers for Hazel Graphite

5. Progress the Current 2025 Portfolio of Hazer Technology customers Fortis BC (Power Gen), Chubu (Power Gen), POSCO (Steel), ENGIE , Energy Pathways (Ammonia) - a very nice mix of geography and industry

6. In parallel, progress discussions on the sales pipeline, particularly with KBR

Having looked at each aspect of the HZR business at some level of detail, it feels like now is a really good investment entry point. It feels like all the pieces of the puzzle for scale-up and commercial acceleration have really come together in the last 24 months. Real opportunities are progressing with the 5 current projects, the sales pipeline is being progressed in parallel and the major cost investments are behind HZR.

Discl: Held IRL 0.72% and in SM

Aside from agreements with Customers and Hazer Graphite Marketers, HZR has entered into 2 key technology partner alliances on the technology expertise and delivery end.

5 MAY 2025: KELLOGG BROWN and ROOT - Binding Alliance Agreement

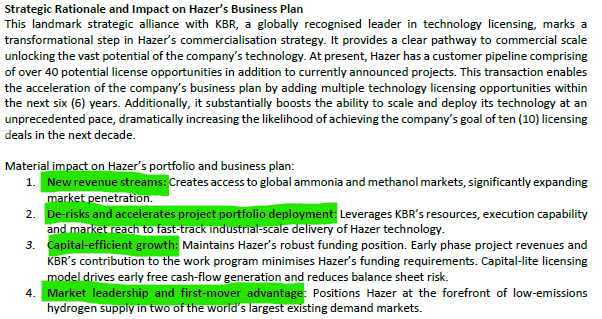

This KBR agreement was a major tick in the box for my thesis as:

- Huge Engineering name with a solid track record in petrochemical plants

- Ammonia & Methanol plants are HZR’s biggest TAM segment given its very dirty CO2 emissions

- Locks KBR, with its 50% Ammonia/Methanol market share, exclusively within Ammonia and Methanol, to the hip with HZR, for a long 6 years duration - this, I think, is a huge step forward, from a technology confidence perspective as well as commercially

- This is another dimension of “things coming together” on the technology/engineering-end - it gives HZR the best shot at accelerating the uptake of the Hazer Process

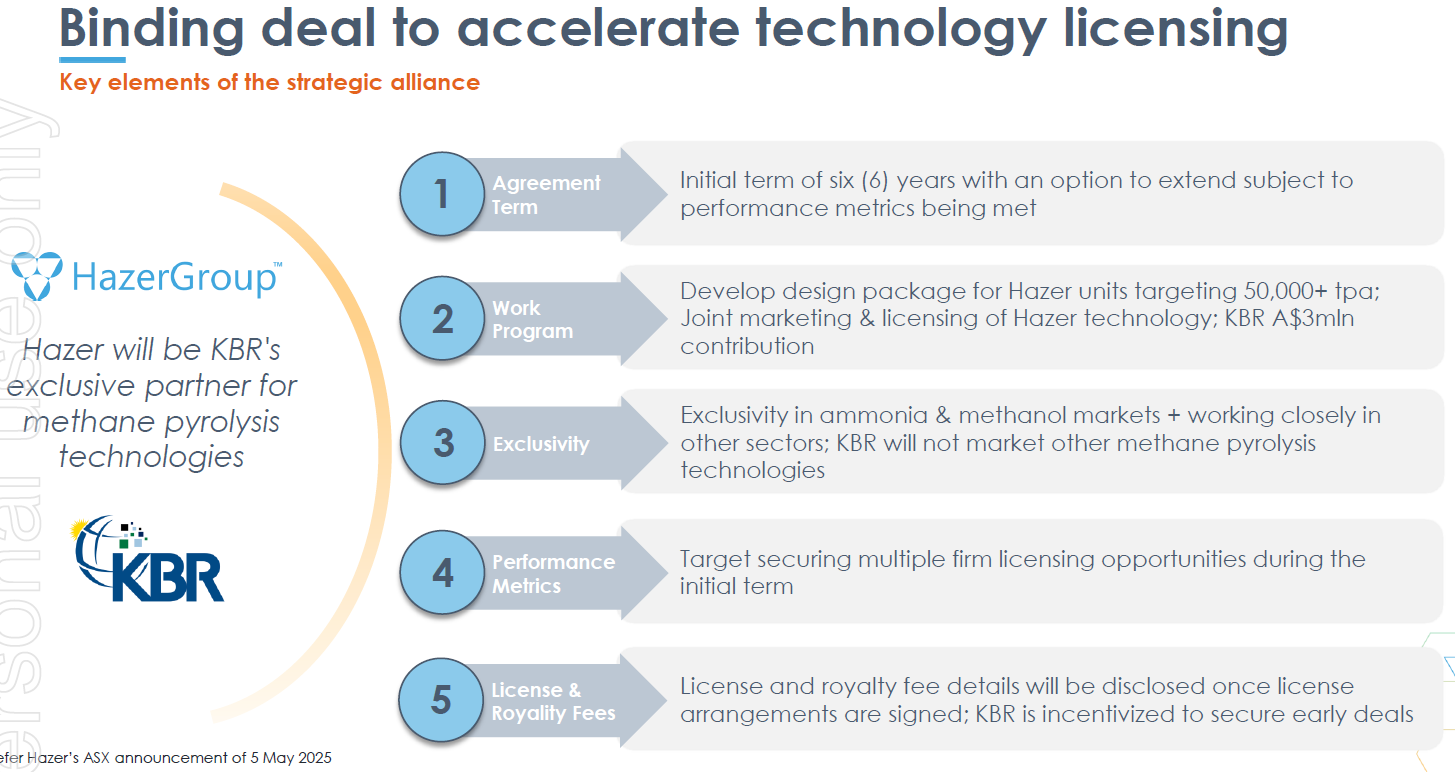

Details of Alliance Agreement

- Binding Alliance Agreement for the commercial deployment and licensing of Hazer’s proprietary methane pyrolysis technology

- KBR will be Hazer’s exclusive global partner for the marketing, licensing and deployment of Hazer technology to customers in the ammonia and methanol markets. KBR and Hazer will also work closely to pursue licensing opportunities in decarbonizing hydrogen markets beyond these exclusive markets

- The initial term of the Alliance is six (6) years with an option to extend subject to the achievement of performance metrics

- Agreed to collaborate on the development of a design package for Hazer facilities targeting hydrogen capacities of 50,000+ tonne per annum as well as the global sales, marketing and licensing of Hazer’s technology. Hazer will be KBR’s exclusive methane pyrolysis technology provider.

- The total cost of the Alliance work program is anticipated to be in the range A$3.0-5.0 million of which KBR will contribute approximately A$3.0 million over the work program period. The Alliance is underpinned by performance objectives with a target of securing multiple firm licensing opportunities during the initial term

- An incentive structure applies in the event KBR secures a license for the first commercial unit secured within three years

- Hazer retains full ownership of its existing intellectual property

The Disruption Opportunity with KBR

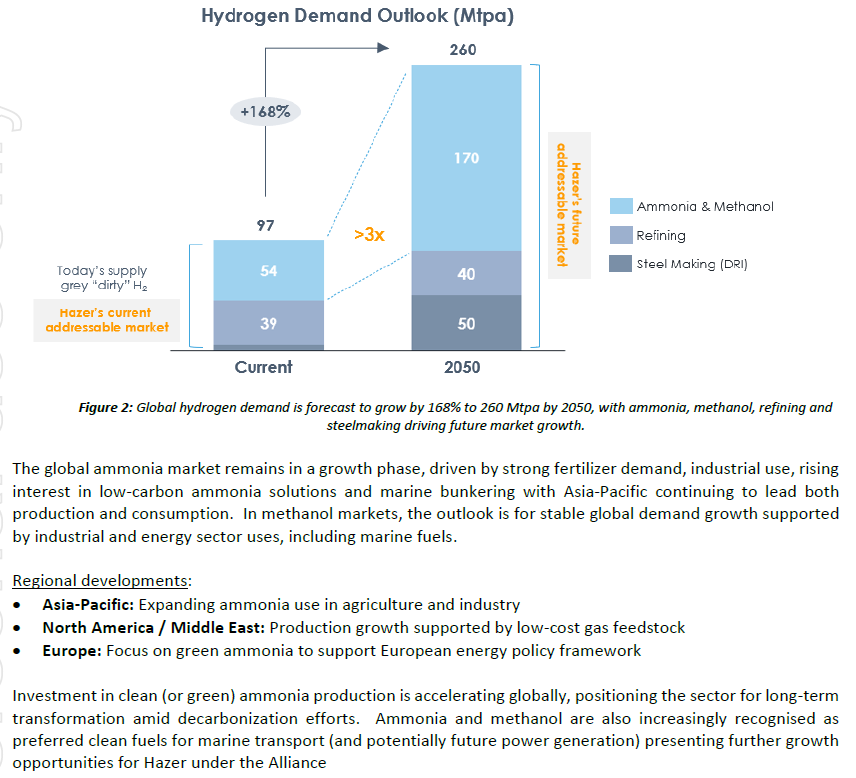

- Hydrogen is critical to ammonia and methanol production, representing over 50% of global hydrogen demand (~54 million tonnes per annum) with the two markets having a combined value of US$120 billion. Current production process used to supply hydrogen to these markets is extremely CO2 intensive, responsible for over 500 million tonnes of CO2 emissions per annum globally

- Under the Alliance, Hazer’s technology will deliver clean and affordable hydrogen supply as the critical feedstock for the ammonia and methanol industries.With KBR’s market leaderhip, the Alliance enables the Hazer process to be positioned as a “bolt-on” low emmissions alternative for both existing brownfields and new greenfield deployments across a large global market.

- Ammonia and methanol are also increasingly recognised as preferred clean fuels for marine transport (and potentially future power generation) presenting further growth opportunities for Hazer under the Alliance

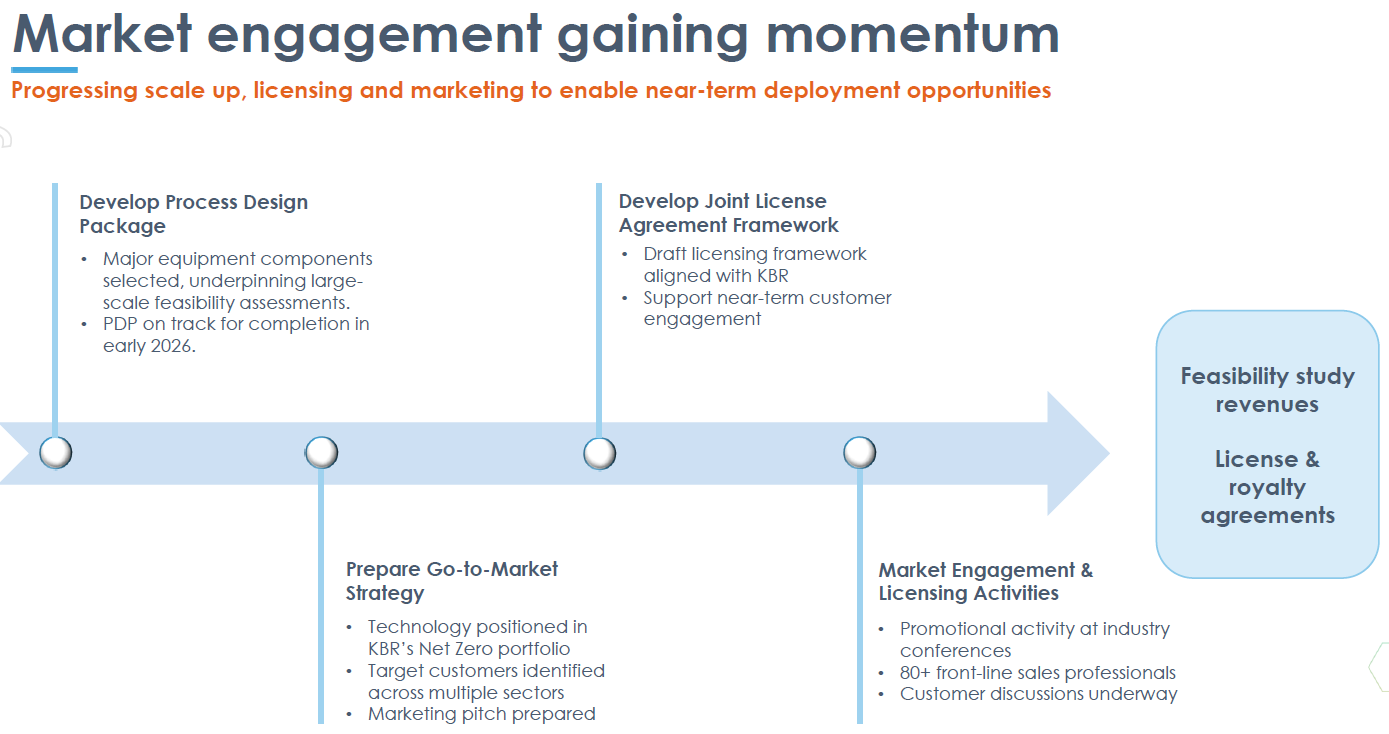

Extract from 15 Oct 2025 Update

KBR Slides from 22 Oct 2025 Microcap Investment Conference

Summary of Progress Update 15 October 2025

10 JUNE 2025: PARTNERSHIP WITH PARTICULATE SOLID REASEARCH INC (PSRI)

- Collaboration accelerate the scale-up of Hazer’s commercial reactor technology.This partnership enables Hazer to leverage PSRI’s world-class expertise in fluidisation fundamentals and process scale-up, further strengthening the pathway to large- scale commercial deployment of its breakthrough technology.

- Hazer’s use of fluid bed reactors is one of its primary competitive advantages

- This partnership with PSRI complements Hazer’s strategic alliance with KBR and enables Hazer to fast-track the development and optimisation of reactor design and integration into these commercial scale applciations.

Discl: Held IRL 0.73% and in SM

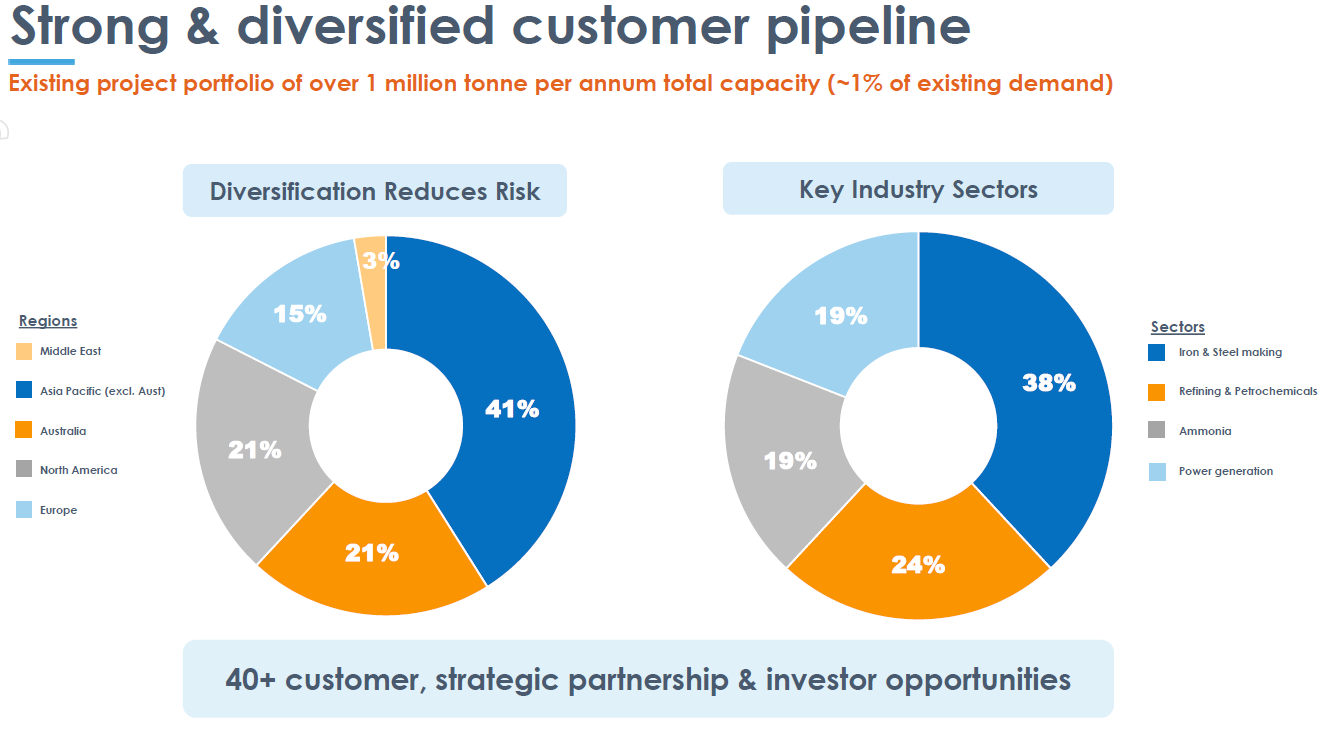

Worked through each of the customer-related Memorandum of Understandings as far back as I could to get a more detailed feel of how it all comes together. There is a lot of detail in each announcement - have summarised the customer projects/MOU’s in the table below.

I am gaining increasing conviction of (1) the technology - it is here and real (2) the opportunities currently on the go and how they are progressing and (3) how the various pieces come together - technology, business model, expertise, graphite.

Will peel HZR’s technology partner agreements next - Kellog Brown Root is a big one, and then PSRI.

HZR'S MARKETS

1. Hydrogen Production Market

2. Graphite Market

Improves the economics of the HZR technology amidst (1) critical Tier-1 need for energy transition (2) China dominates supply and tightening export processing technology and IP (3) HZR is a local, high purity, low emissions alternative.

Graphite is a key component in lithium-ion batteries, electric vehicles, renewable energy storage systems and numerous industrial applications

The Hazer process produces high-purity graphite with unique product characteristics well suited to advanced applications, steel making, cement and asphalt, PFAS remediation and thermal energy storage

3. Sales Pipeline

Very strong global pipeline, with large amounts of potential hydrogen production capacities.

Asia is one of the world’s largest hydrogen markets with regional demand in 2024 of approximately 40M tonnes per annum - almost 40% of the global hydrogen market and growing steadily at around 4$ annually

CUSTOMERS AND PROJECTS CURRENTLY ON THE GO

Worked through each of the customer-related Memorandum of Understandings as far back as I could to get a more detailed feel of how it all comes together. There is a lot of detail in each announcement - have summarised the customer projects/MOU’s in the table below.

I am gaining increasing conviction of (1) the technology - it is here and real (2) the opportunities currently on the go and how they are progressing and (3) how the various pieces come together - technology, business model, expertise, graphite.

Will peel HZR’s technology partner agreements next - Kellog Brown Root is a big one, and then PSRI.

KEY TAKEAWAYS

- Very insightful to see the sorts of hydrogen and graphite production collaborations/MOU’s that HZR has signed up to and are working on

- There is good, steady and positive progress across all projects other than Engie - need to check why that seems to have fallen off the radar.

- The Fortis BC project is particularly exciting in terms of (1) size, 25x that of HZR’s Commercial Demonstration Plant in WA (2) where it is at - successful completion of Commercial Reactor Test Program (3) The British Columbia government support (4) receipt of first revenues and (5) the potential licensing commercial terms during production which could be on a sliding scale model based on size of the facility, production of hydrogen and graphite and other relevant factors

- Each commercial agreement executed in a producing Hydrogen facility is likely to be a step up in long-term recurring revenue - this is very exciting in terms of future revenue stream possibilities - this revenue will grow as the producing plant scales eg. Chubu Electric

- Good to see how the various pieces have come together in the MOU’s/Projects - (1) the role of the Commercial Demonstration Plant in proving the concept (2) the application of the Hazer technology in a real-life site/environment (3) the role of Hazer Graphite in significantly improving the production economics (4) the various MOU’s to commercialise Hazer Graphite, offtake opportunities etc

- Sales Pipeline looks extensive and makes sense in terms of where HZR is targeting the use of the Hazer technology

KEY RISKS THUS FAR

- Very long gestation period from start of concept/feasibility to a producing plant

- There is no deal until there is a deal - this is an ongoing risk, but appears to be well mitigated with steady progress, robust technology and economics, and good technical capability partnerships, but this is still the biggest risk

Customer Projects/MOU's Signed

May not be complete but gives a good idea of the sort of MOUs and capacities being investigated. This was what I could find in the announcements.

Discl: Held IRL 0.67% and in SM

Part 1 of a few parts as I deep dived on HZR.

SUMMARY

HZR owns the IP to the Hazer Process and is developing and commercialising this technology

The Hazer process is a low-emission method for producing hydrogen and graphite from natural gas or biogas. It uses a low-cost iron ore catalyst to crack methane into hydrogen gas and solid, high-quality graphite. This process offers a cleaner alternative to traditional hydrogen production by capturing the carbon as a valuable solid product instead of releasing it as carbon dioxide.

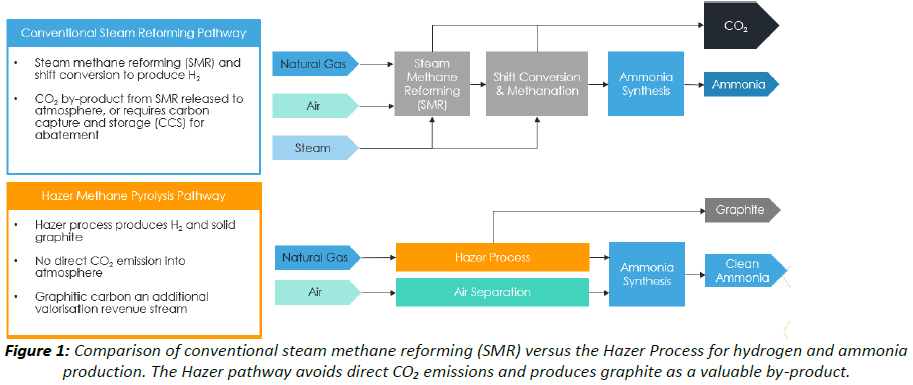

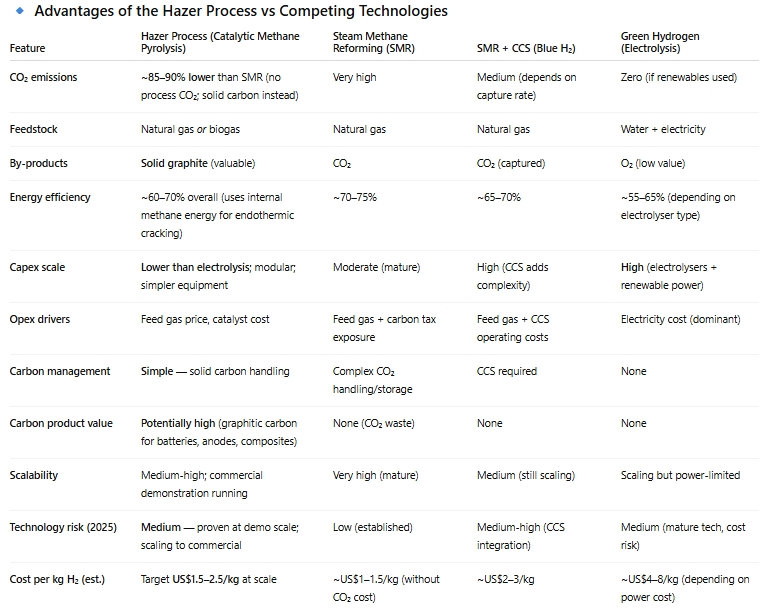

There are significant benefits to the Hazer Process vs the current dominant Steam Methane Reforming (SMR) method of producing hydrogen - zero carbon emission, low energy requirement, no requirement for carbon capture storage, valuable carbon graphite co-product which can be monetised

The Hazer Process is categorised as a “methane pyrolysis” method of producing hydrogen

Other companies have developed variations of the methane pyrolysis method, but the Hazer process is differentiated by the following advantages: (1) the use of Iron Ore as a catalyst (2) creates high quality Graphite Carbon as a co-product (3) avoids need for carbon capture storage (4) low electricity cost

The choice of which methane pyrolysis methods for a given plant/site will depend on several factors, including (1) energy source & footprint (2) scale & deployment model (3) carbon product quality

The focus in the past few years has been to build the Commercial Demonstration Plant (CDP) in Munster, WA, which has been fully operational since Nov 2024 - this was a key milestone to demonstrate the commercial readiness of the Hazer Process technology

WHAT IS ATTRACTIVE

The Hazer process has huge technology advantages over current methods of producing hydrogen, including other alternative methane-pyrolysis approaches

Hard yards to scale up and prove the Hazer process has already been done - the technology appears to be ready for scale-up and commercialisation

This is feeling very much like C79, minus the Capex spend on the Photon Assay machines - the Hazer technology is set to disrupt the current dirty method of producing hydrogen by offering a more efficient and clean approach, with the economic benefit of high quality carbon graphite as a co-product which can be monetised

A. BUSINESS MODEL

Has IP rights to a technology developed a The University of Western Australia which allows the production of hydrogen gas from methane (natural gas) with negligible carbon dioxide emissions and the co-production of a high purity graphite product (the “Hazer Process”)

Business model is focused on scaling-up and commercialising the Hazer Process so as to supply hydrogen gas and high purity bulk graphite to the significant global hydrogen and graphite markets.

B. HAZER’S MISSION

Our mission is to play a significant role across three multi-billion dollar global markets. Hazer Group’s technology can potentially provide an innovative solution for the global industrial hydrogen market, by producing hydrogen at lower cost than alternative options, while also reducing users’ CO2 footprint.

The low-emissions associated with the HAZER Process also potentially provides a gateway for hydrogen to more effectively penetrate the sustainable energy market for both vehicle fuel and stationary power applications. Hazer is also looking to provide high quality synthetic graphite for energy storage and other large global graphite applications.

C. THE HAZER PROCESS

The Hazer process is a low-emission method for producing hydrogen and graphite from natural gas or biogas.

It uses a low-cost iron ore catalyst to crack methane into hydrogen gas and solid, high-quality graphite.

This process offers a cleaner alternative to traditional hydrogen production by capturing the carbon as a valuable solid product instead of releasing it as carbon dioxide.

HAZER’S DISRUPTIVE ADVANTAGE - METHANE PYROLYSIS METHOD vs INCUMBENT SMR TECHNOLOGY

The Methane Pyrolysis technology method has very clear economic benefits over the current Steam Methane Reforming (SMR) method BUT HZR is not the only company with technology in the Methane Pyrolysis space.

Discl: Held IRL 0.67% and in SM.

Continuing with Part 2, focusing on the competitive landscape and Tech Readiness for Commercialisation

COMPETITORS WITH METHANE PYROLYSIS TECHNOLOGY

Methane pyrolysis requires approximately half the amount of energy required by steam reforming to produce the same amount of hydrogen. Finally, the solid carbon byproduct can be sold as carbon black, offsetting the cost of hydrogen produced. Together, these factors make methane pyrolysis a promising technology option to produce low-carbon hydrogen.

Methane pyrolysis takes different forms, and they can be categorized as plasma, catalytic, and thermal

In methane pyrolysis, all the carbon content in the methane is captured in solid form rather than emitted as carbon dioxide

About 44% of methane pyrolysis technology developers are based in the U.S. or Canada, where the feedstock price is cheaper than in Europe and Asia. The attitude toward repurposing existing assets in North America is also more favorable than in other regions, considering that the only operational commercial methane pyrolysis facility is located in the U.S., and the second one is being planned in Canada.

Practical implications — why the methods matter to buyers / project owners

Carbon product quality drives value: Hazer emphasises graphitic carbon (battery anodes / high-value applications). If a competitor produces amorphous carbon black, the co-product value and markets differ. That affects project economics.

Energy source & footprint: Plasma approaches are electricity-intensive (cost + grid emissions matter); microwave and molten-media concepts claim efficiency advantages — Hazer claims lower electricity intensity by leveraging catalytic chemistry and heat integration. Buyers compare energy cost per kg H₂ and grid carbon intensity.

Scale & deployment model: Some firms aim distributed, point-of-use hydrogen (microwave, Aurora), others aim industrial replacement markets (Monolith carbon black), and Hazer targets licensable commercial modules with graphite offtake economics. Choice depends on the customer (industrial vs mobility vs battery material players).

PATENT PROTECTION

- HZR has 70+ IP patents in its IP portfolio in different countries to protect its ownership of the IP

- Full list is maintained at Patents List

TECHNOLOGY READINESS FOR COMMERCIALISATION

Extract from: https://research.csiro.au/hyresource/hazer-commercial-demonstration-plant/

- Focus in the past 3-4 years has been to build and develop the Commercial Demonstration Plant (CDP) to demonstrate the readiness of the technology in a real-life plant environment - located in Munster, WA

- The CDP has been operational since Nov 2024

- Virtual Tour of the Commercial Demonstration Plant:

Discl: Held IRL and Pending in SM

I like it when I gain immediate conviction on analysing a new company. And so it is with HZR this morning.

I will deep dive in the next 1-2 days, but I read the Q1FY26 Preso released this morning, had a look at what the Hazer technology is and does, and pulled the position open trigger 10 minutes into the webinar at $0.52. More detail to follow.

High-Level Position Opening Thesis

- Technology is affordable, scalable and available now - ready to disrupt, after 17 years of developing the technology into an advanced state - $130m development capex cost is now in the past

- IP Owner, licensing model, so capital light

- Global alliance with KBR - big engineering tick to advance commercial scale-up and go-to-market strategy

- End Products of the Hazer Process - Clean Hydrogen and Graphite - huge market demand for both products. Market is aligning to the Hazer technology benefits and technology availability

- Graphite Market dominated by China (80% of processing and supply) - tightened export controls - HZR offers a local, high purity, low emmissions altenative - this is a significant differentiator from other clean hydrogen processes, geo-political developments mean planets are aligning for Graphite

- Global sales pipeline looks impressive - management is focused on "quality over quantity"

- Financials are growing nicely - $20m of funding available, low operating cost base with a focus on continued cost discipline

CHART

The HZR price is in a nice support resistance zone of $0.51 to $0.555. It feels like this is a fair price and entry point given the technology de-risking that has occurred in the past year, and the potential commercial scale up that occurs from here.

Immediate downside support is $0.45 - if my deep dive confirms this initial feel, will be topping up, up to these levels. Given where the company is at the moment, the technology de-risking, the opportunities, this feels like a very defendable floor.

For those new to the stock: HZR is a WA-based technology development company undertaking the commercialisation of the HAZER Process, which enables the low-emission, efficient conversion of natural gas and similar methane feedstocks into hydrogen and graphite using iron ore as a process catalyst.

A potted history: I was attracted to HZR because of the chemistry and the possibility of a future technology. I took a small position in 2021 and sold out in 2023 (at a loss) - very annoyed that the then-board had taken the (highly green) tack of making their first RL project a biomass deal - to convert the methane from a biomass facility that they proposed to build at Busselton, WA. The project was dependent on state government support, which predictably didn’t eventuate. So after lots of commitment into design, etc, the company was left with…nothing. Complete failure.

In hindsight, it's possible that that failure - and ironically, the WA government’s hand in it - will in the end turn HZR into the company it always could’ve/should’ve been.

Enter Glen Corrie as CEO. He refocused the company on generating “turquoise” hydrogen (from methane from LNG - so there’s a small amount of emissions in the sourcing of the gas, but down the track, that could be addressed as well.) Still, he never claims the Hazer product is completely green hydrogen.

Fast forward three years to now:

In 2024, the Commercial Development Plant passed all trials with flying colors, and FortisBC were an early potential partner to actively engage. FortisBC are a renewable energy, gas, and electricity utility in British Columbia..

This is the Hazer process:

I have to say that Hazer have become heaps better at communicating and explaining what the process is and what advantages it has.

And now, it’s a go on several fronts.

One of the factors that moved me to buy back into HZR last year was that Corrie has set it up as pure licensing. NO building anything, and the patent portfolio is broad and deep.

However, as shown in the above, like most similar businesses, HZR faces a lumpiness in income due to the lag between inking an agreement and the partner’s facility coming fully online. They are addressing that by ramping up efforts to draw in more partners/sites - which gets easier the more agreements they sign.

And through a seriously helpful strategic alliance with KBR

AND…then there’s the graphite.

Putting it all together:

So HZR seems to be hitting its stride (finally). Much kudos has to go to Corrie’s leadership, and thankfully, he’s just signed on for another three years.

Of course, lots can still go pear-shaped, and HZR remains a speculative play, but step by step, month by month, it’s getting closer to take off.

One facet of the HZR story that continues to fascinate me is that at no time has WDS - which is sitting right there next door in WA - ever shown any signs of buying HZR. Just think about it. If WDS has a massive supply of LNG and also has exclusive rights to the HZR process, which turns that LNG into the closest thing to readily transportable liquid “green” fuel...

Discl: Held in RL.

Added a few more IRL as a result of the following ASX release this morning.

HAZER ACHIEVES FIRST HYDROGEN AND GRAPHITE AT COMMERCIAL DEMONSTRATION PLANT:

Highlights:

First hydrogen and graphite production from CDP successfully achieved.

Ramp up of operation to continue through H1 2024 leading to continuous production.

World’s first commercial-level demonstration of Hazer methane pyrolysis technology producing clean hydrogen and graphite.